You can have the most high-tech maintenance plan ever, but if your team isn’t ready to use it, it’s like having a basketball playbook but no one even knows how to dribble. The real magic? That happens when your crew actually brings the plan to life, making sure everything runs smoothly and lasts longer. Parang sa barangay liga, hindi sapat ang drawing ng play—kailangan may execution din!

For this career episode I sent to Engineers Australia, let me kwento how I faced a big challenge: our local team was having a hard time with the basics of maintenance planning and engineering. My role? Not just to make and teach a training program, but also to get my hands dirty and help everyone actually use what we learned on the job site. Parang teacher na hindi lang sa classroom, kundi kasama rin sa field—literal na hands-on!

My goal was simple: help the team stop being abangers sa last-minute repairs and start getting ahead of problems. We wanted everyone to feel confident, work smarter, and keep things running smoothly—walang aberya, sana all! I combined classroom lessons, hands-on workshops, and real-time guidance on site. By the end, the team could handle maintenance like real pros, no need to panic or call for backup every time may sumablay.

CAREER EPISODE 3

From March 4, 2020, to the present, I have been employed as an expat Mill Planner Trainer for Kumtor Gold Company and assigned to the Mineral Processing (Mill) Plant located in the Kyrgyz Republic. Its head office is at 24, Ibraimov Street, Bishkek, Kyrgyzstan. My primary duty is to support the professional growth of the local staff members in Mill Maintenance, Planning, and Engineering by improving their technical skills and knowledge.

Kumtor is one of the highest gold deposits in the world and is situated in the southern region of the Central Tien-Shan at an altitude of 4,000 meters above sea level in a permafrost zone. The gold deposit is located 350 kilometers from Bishkek, the capital of the Kyrgyz Republic. Kumtor Gold Company is the first and most important operation in the Kyrgyz mining sector. Kumtor’s gold production accounts for more than one-third of the country’s exports of goods and services. Being a very important company, Kumtor hired engineering specialists like me to develop its manpower and be capable of delivering results and improvements in equipment management.

BACKGROUND

I hope to show through this career episode that I can effectively convey engineering concepts, modify training methods for a variety of audiences, and support the professional development of local Kumtor personnel.

The training program, which covers subjects like fundamental engineering standards, improvements to the Computerized Maintenance Management Program, improvement of maintenance records, workforce productivity, maintenance planning procedures, and standard equipment mechanical parts, is the result of my extensive experience in equipment maintenance and planning. I customized the workshops and training sessions for the participants, who ranged in experience from mid-level engineers to interns, based on their varied backgrounds.

As the Mill Planner Trainer, my role involved meticulously designing the training program, selecting appropriate teaching materials, and preparing engaging presentations. To guarantee active engagement and knowledge retention among the staff, I used interactive teaching strategies, such as practical examples and hands-on exercises.

Below is a simplified table of organization of Kumtor where I indicated the chain of command which I am involved with. I report to the Planning and Engineering Superintendent and to the Mill Senior Planning Engineer. My role is not only to train and conduct workshops, but I am also actively providing specialist and technical engineering input aimed at meeting the goals and objectives of the Maintenance, Planning, and Engineering Department.

PERSONAL ENGINEERING ACTIVITY

Kumtor has lined up several projects like Tower Mill Installation, Carbon in Leach Tank, and Agitator Installation, upgrading of the Sag Mill pump discharge pipeline, and other mechanical installations and parts replacements. I am one of the major personnel who guided and directed the local employees with the selection of equipment, and design of pipelines and auxiliaries and assisted in the project management.

As an example, I coordinated with the Metallurgy and Operations Department to gather the pertinent properties of the slurry being pumped to the Tower Mill hydro cyclones. I then determined both the slurry head and its equivalent water head in order to optimize the hydro cyclone feed pump selection.

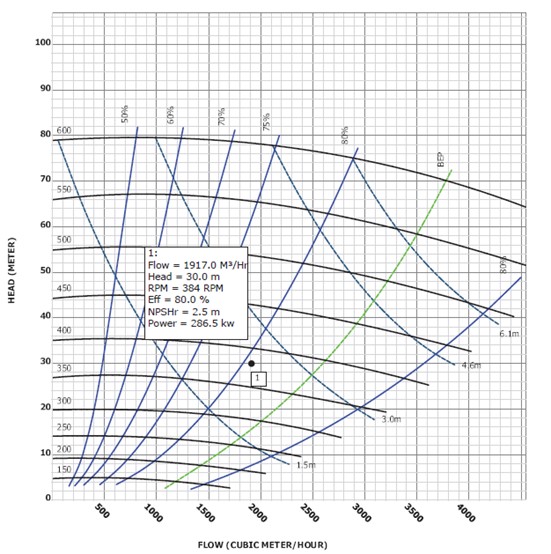

Based on the flow rate requirement of 1,917 cubic meters per hour and the slurry head of 30 meters, I concluded that a 16×14 slurry pump is capable of this particular application. Based on the 16×14 pump curve (see figure below), I determined the appropriate pump motor power and RPM values which are 286.5KW and 384RPM respectively.

To determine the appropriate motor size for safety and efficiency, I advised installing a motor with some additional capacity to account for potential variations in operating conditions and to ensure efficient pump performance. Which in this case is a 480KW, 1,000RPM motor.

My involvement in these projects gave me the opportunity to evaluate the local employees’ training needs. In performing the training needs analysis, I applied the direct observation method and consultation with supervisors and superintendents. One of the skill gaps that I observed is their lack of basic mechanical engineering knowledge. Engineers who possess a basic understanding of engineering are better equipped to examine and resolve difficult technological issues. Using this, I gave training on the principles, codes, and standards of process piping. In developing my training modules, I applied the PDCA (Plan, Do, Check, Act) cycle.

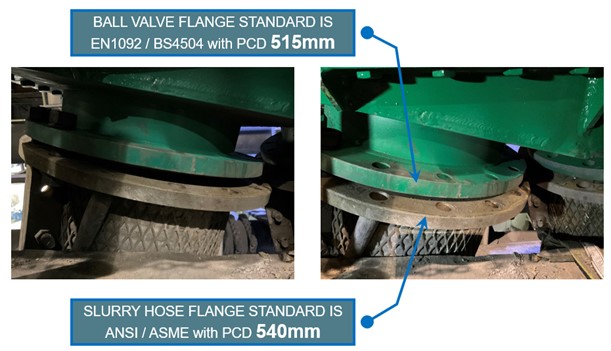

The figure above shows the error in purchasing an auto ball valve worth $5,000. Before my training, the local engineer ordered a valve with British Standard flange connections while the hose flange was ANSI standard. I then specifically emphasized in the training the different standards of process pipelines, flanges, and other auxiliaries. Aside from the piping design codes and standards, I also included in the training module the basics of the process piping system, definitions, terminology, and essential vocabulary.

I also highlighted in the training the simple computations that they need to fully understand when selecting a pipe schedule and how to determine nominal pipe size. During the training, I informed the interns and engineers of the frequently used pipe materials in the Mill plant, the different pipe constructions which are Electric Resistance Welding and Seamless pipes, and the specific applications of each type.

As a result, the Mechanical and Planning Engineers were already equipped with knowledge of the Piping system. As a follow-up, I routinely checked the pipe and auxiliary parts design and procurement done by the engineers. I did one-on-one training as well, I explained to my trainee the material specification, structural analysis, and manufacturing processes of mechanical components to be able to design and procure parts that are safe, efficient, and cost-effective.

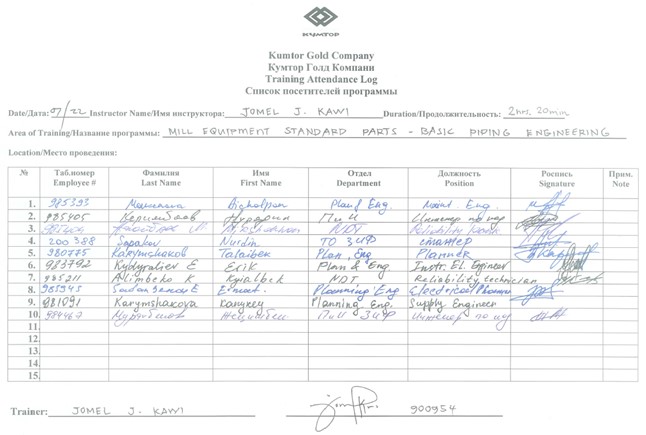

The table above shows the attendees of my Piping standards training. In order to ensure adherence to industry standards, laws, and safety protocols, a basic understanding of engineering is required. I explained to the local engineers that they need to understand the legal and safety requirements associated with the projects to design, parts to procure, and implement solutions that meet these standards. This information promotes risk mitigation, hazard prevention, and environmental and human welfare.

Aside from the Piping standards training, I also conducted several other Planning and Engineering-related trainings for the local employees which addressed various skills gaps that I identified during my employment in Kumtor. I shared my in-depth understanding of Mill equipment maintenance and planning procedures which I gained from my previous job at Philex Mining Corporation. These are the following:

Inventory Control and Management of Mill Parts Training. This training demonstrated how I helped the local staff become more proficient at controlling the inventory of Mill equipment parts, optimizing stock levels, putting in place effective control systems, and making sure everything runs well at the Kumtor Mill. Effective inventory management was essential to achieving cost control, minimizing downtime, and meeting production demands. I actively participated in projects to improve inventory management and control procedures in order to achieve continual improvement. I performed process enhancements and identified opportunities for improvement through routine data analysis and performance evaluation. This included optimizing reorder points, implementing safety stock levels, and refining inventory replenishment strategies based on demand variations and lead times.

Weekly Maintenance Planning and Scheduling Procedure Training. In my capacity as an expert in Maintenance Planning, I honed the skills of Kumtor planning engineers in the areas of developing maintenance plans, maximizing resource utilization, putting scheduling strategies into practice, and guaranteeing the efficient completion of maintenance tasks. The measurable results of my involvement in weekly planning and scheduling included improved equipment reliability, increased operational efficiency, cost savings, and enhanced safety.

Basic and Advanced Microsoft Application Functions Training. To perform engineering reports, analyses, computations, and designs, it is imperative for a professional engineer to become proficient in a variety of software programs. With this, I have mastered Microsoft applications and shared my skills with the local engineers of Kumtor. This demonstrated my efforts to provide staff members with the necessary software skills and to encourage effective use of Microsoft products throughout the company. Increased employee satisfaction, cost and time savings, increased productivity, and improved teamwork were among the quantifiable outcomes attained. By promoting efficient utilization of Microsoft applications, I contributed to the organization’s overall efficiency, effectiveness, and employee development.

Capital Project Cost Control and Monitoring Training. As part of my objective to improve the project management in the Mill plant, I conducted this training which developed local engineers’ cost control strategies. Together with ensuring efficient cost management throughout the project lifecycle, I also set up strong monitoring mechanisms. In relation to this, I also conducted training about Annual Budget and Cost Centers. I trained the local engineers one-on-one on how to develop the Mill’s Annual Budget and Cost Center management. This highlighted my contributions to developing annual budgets, establishing cost centers, and ensuring effective financial management through budgetary control.

Mill Equipment Standard Parts Training. For a Mechanical Engineer to conduct design improvements, capacity increases, and material upgrades it is important to identify basic Mill equipment standard parts. I was able to help local engineers identify common parts and components that needed regular maintenance or were often replaced, thanks to this training. Among these parts were fasteners, sheaves, gears, v-belts, seals, bearings, and bushings. I also developed a parts catalog that listed all basic standard parts identified for the Mill equipment. Maintenance professionals would find it easier to locate and order necessary components with the help of this catalog, which provides comprehensive specs, part numbers, and supplier information.

I conducted training regularly to fulfill my responsibility as a Mill Planner Trainer which is to contribute to the professional growth of local engineers. Here are the other topics that I conducted online (MS Teams) and hands-on: a) Identification of Mill Critical Parts and Periodic Monitoring Procedure, b) Daily Parts Withdrawal reporting, c) PM Compliance – Planned vs. Unplanned Maintenance, d) Daily Mill Maintenance Performance reporting, e) Mill Maintenance Key Performance indicators.

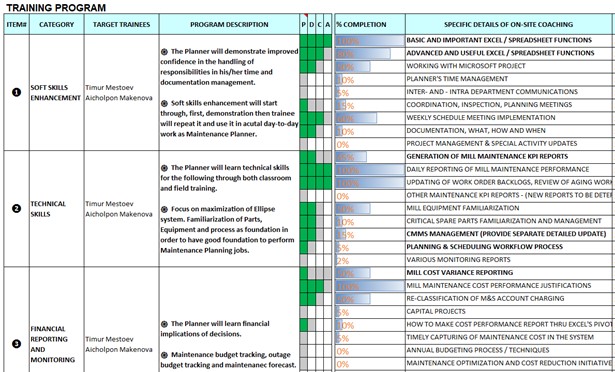

Here is an example of my training program in the table. It featured technical know-how, soft skill development, and additional reporting abilities needed to carry out routine maintenance planning tasks.

Mechanical Engineering is a dynamic field that constantly evolves which is why I continuously learn and adapt by updating my skills and knowledge specifically in Mill equipment maintenance management. With the new projects of Kumtor Mill, I researched new mechanical technologies that would advance the performance or capacity of equipment, processes, or systems. I collected the current campaign life of pipelines, the capacity of existing pumps, and other unsatisfactory mechanical designs that restrict production and/or contribute to high maintenance costs. After that, make use of this data to put design solutions into practice and/or check performance versus requirements.

SUMMARY

Through the delivery of comprehensive maintenance planning and basic engineering training sessions, I successfully contributed to the skill development and knowledge enhancement of local employees at Kumtor Gold Company, specifically Mill Departments.

My training sessions produced better maintenance procedures, more operational effectiveness, and more engaged staff. I was instrumental in giving the Mill staff the abilities and information they needed to succeed in their positions by offering excellent training opportunities and encouraging a culture of lifelong learning. This helped Kumtor’s overall success.

Article by: Engr. Jomel J. Kawi